What are the benefits of product tracking?

Complaints and compensation

In the event of quality problems, it is important to know which supplier the raw material of the product in question came from. This data can be viewed at the touch of a button, as it is not only the finished product that receives a unique identifier, but also the raw materials entering the factory or warehouse.

Product recall

Unique product tracking is a risk-mitigating tool that helps you to react in time in the event of anomalies: If a problem occurs, the manufacturer can recall the goods in a matter of seconds, and only those affected by the error, no more no less.

Compliance with regulatory requirements

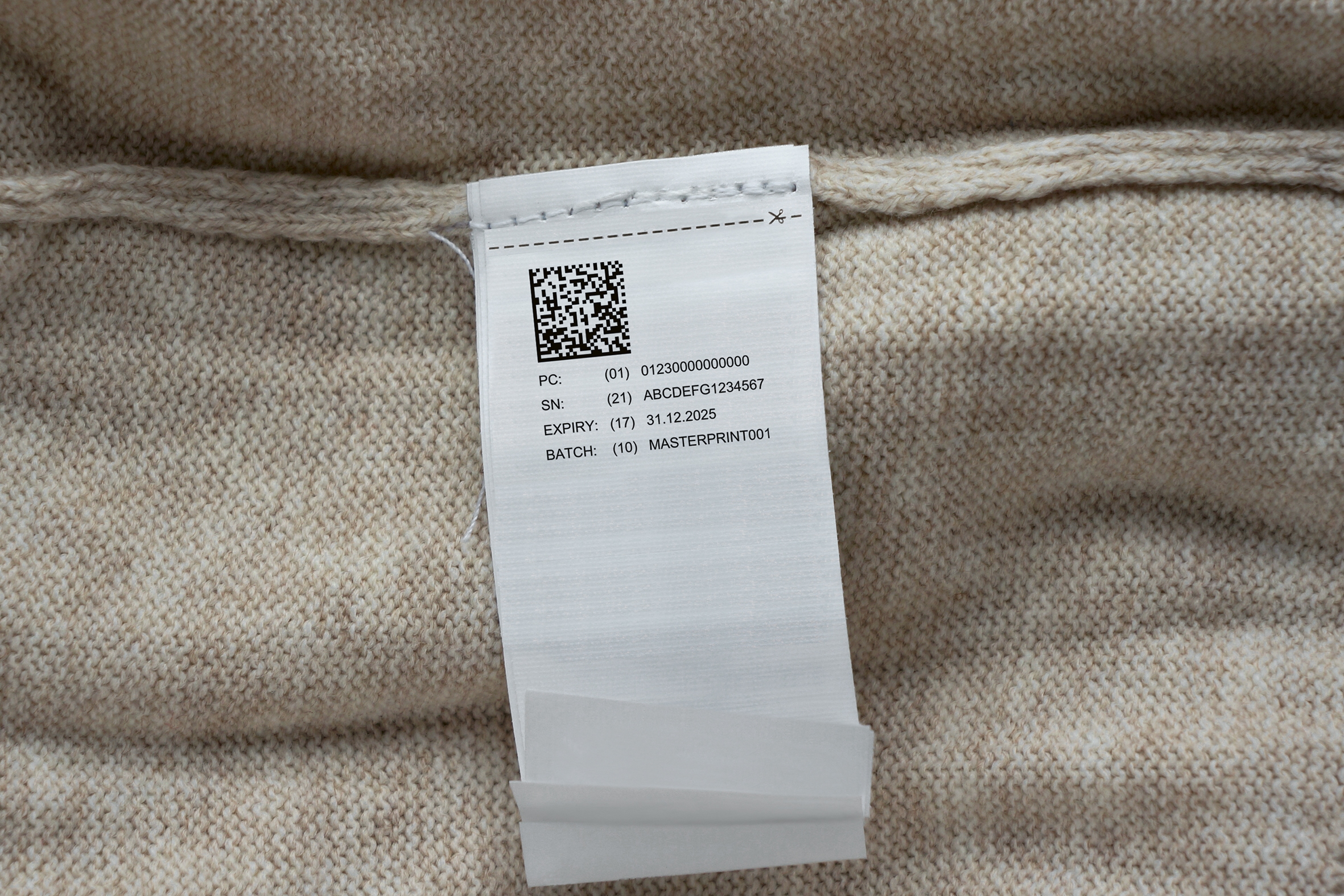

In industries in which product traceability is an official requirement, unique identification is the perfect solution. Pharmaceutical and chemical companies have been required to track the entire life cycle of individual commodities for years now, making abuses preventable.

Counterfeiting

It helps to protect your company’s reputation against counterfeiting. The prestige of a brand built with a lot of hard work can depend on customers being guaranteed authentic products rather than imitations.

Fewer expired products

It is possible to reduce losses due to expired products, increase logistics and distribution efficiency, and increase supply chain reliability. This is because the system also stores the expiry information of the raw materials, so everything can be used in the right order during production.

Customer trust

Tracking information also has a monetary value: Many customers are willing to pay more for a product they receive more information about. Customers prefer choosing identifiable products and transparency inspires trust in the customer, making them feel more secure.

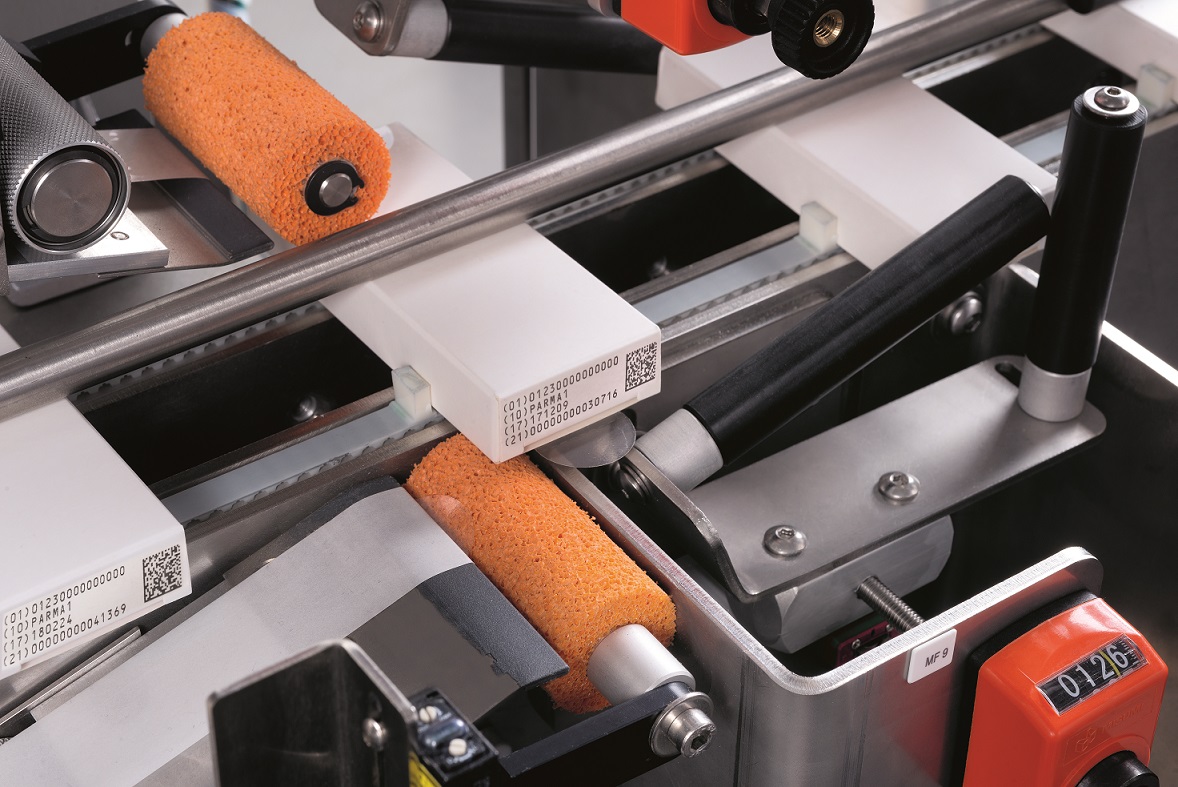

Tracking solutions in the pharmaceutical industry

Our complete systems help the pharmaceutical industry to meet EU standards. The aim is to provide the ability to trace each product from when the raw materials for making medicines arrive at the factory to when products are delivered to customers. This makes the whole process transparent, filters out counterfeits and prevents various abuses. Our serialization stations and systems, together with the associated hardware and software, can be integrated into even the fastest production lines. For many years now we have been successful in the complex and ever-changing world of pharmaceutical marking technology. As a result of this we have gained a lot of important experience in the field of product tracking.

Track and Trace solutions in the field of agrochemistry

It is extremely important to monitor agrochemicals from their production until they arrive on farms. This is the only way to keep the amount of chemicals in food within acceptable health limits. Track and Trace systems are also good at helping curb product counterfeiting by tracking chemicals. Since the packaging of extremely hazardous materials must be uniquely identified, the stations are designed to perform to high quality standards and for a long time, even under extreme conditions. The printed image is perfect, regardless of whether it is liquid or solid products that are being packaged.

Product tracking in the food industry

There are several reasons why more and more food industry businesses are introducing unique product tracking. On the one hand, it helps them meet the extremely strict health and quality requirements. And on the other hand, the easiest way to protect brand reputation is to trace the entire life cycle of each product from the raw material through the production of the finished product to its delivery to the consumer, thus ensuring that origin of the product is transparent and its quality is high. Customer demand has increased, the place of origin of raw materials has become important information, and customers also want to purchase top-quality food – the end product of a transparent process. Our stations, which we developed ourselves, put unique identifiers on boxes, cans and trays according to the various packaging processes of the food industry. This increases the customer’s sense of security and improves production efficiency.

Customized Track and Trace solutions

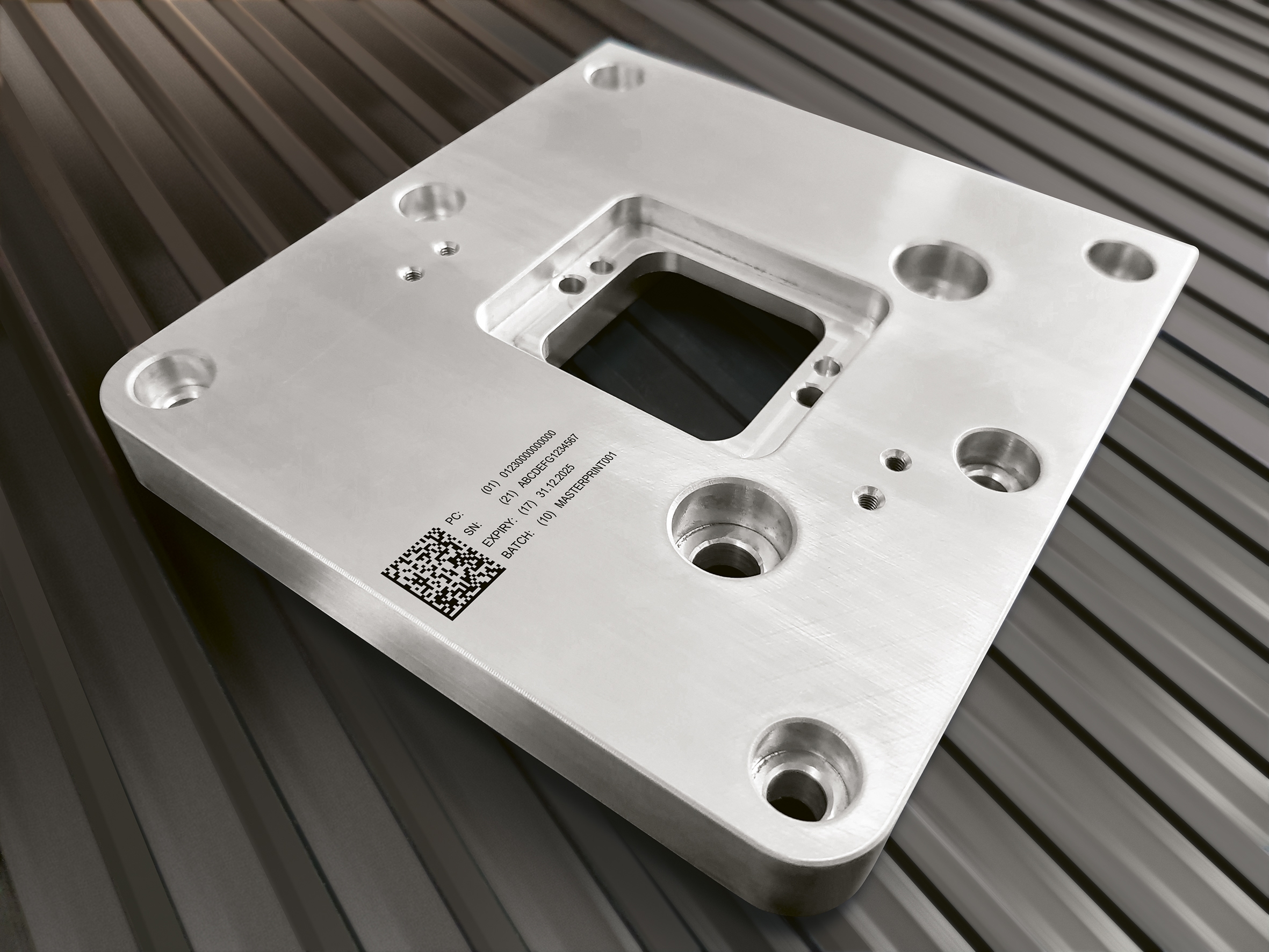

Here at Masterprint Kft., we apply markings regardless of industry. Essentially we can print on anything. We think in systems – whether it’s a specialized production line, a rare product, or product identification. The equipment we employ is of premium quality, and our staff find compact, economical and creative solutions that meet the labeling requirements of the most unique products or production environments. We provide solutions for needs that sometimes literally develop overnight, including expectations about unique product tracking.

Food safety, identifiable medicines and product recall in case of emergency. The purpose of tracking and tracing is to ensure quality and origin, to establish transparent corporate processes, to comply with regulatory requirements and much more. Unique product tracking is an extremely useful tool for any manufacturing company, regardless of the industry. Our philosophy is to provide our partners with the simplest and easiest-to-use systems. After all, the goal is not to make their jobs more complicated, but to make them simpler.

Software

Masterprint Linemaster™

Our central print control and monitoring software solutions are needed when production at a plant expands, when packaging, marking and labelling is already carried out on several production lines, and when several types of products are produced. Downtime increases during changeover, as it takes time for every machine to be calibrated. But it’s not just the time spent on changeovers that is lost, central print control can also eliminate errors. With our INDUSTRY 4.0 compliant software, printers, PLCs, quality control cameras and other devices can be integrated into and controlled from a single system, and production instructions can also be issued.

Masterprint Sitemaster™

Sitemaster is not a corporate management system, but a product and raw material tracking system that we developed specifically for unique product identification. This is a central program that runs on any given factory’s server, providing an overview of each stage of production, where the products are marked and where the markings are read. The entire life cycle of each product can be traced back in the system, step by step.

Not only the finished products receive unique identifiers, but also the raw materials that enter the production site or warehouse. In the event of complaints, it is easy to trace which supplier the raw material of the product concerned came from.

Hardware

PharmaJet DMP6

PharmaJet Print & Check Tamper Evident

PharmaJet Print & Check Tamper Evident Aero

Chemical Serialization Station

Semi-automatic Case Aggregation Station

Central print control

The MasterPrint T&T MQTT central controller is a PLC-based device. It is responsible for the communication between all its connected devices and the MasterPrint LineMasterTM software during the product identification process. Its great advantage is that any device can be connected to it, and our software solutions can control the devices both installed on the production line already and the devices we have installed.

With the help of our industry-independent central print control, printers, PLCs and quality control cameras can be flexibly integrated into and controlled from a single system, and production instructions can also be issued. We program and set up the machines from a central database, monitoring what is happening. By eliminating downtime and errors caused by transitions, this solution greatly increases production efficiency.

About us

Our story began 14 years ago, and today our equipment and systems are used in 23 countries around the world. Creating innovative hardware and software solutions in the areas of marking and coding, automation and Track & Trace. This is our main vision. We guarantee the reliability and quality of our solutions through our continuous cooperation with the world’s leading manufacturers and our more than a decade of experience in the field of serialization.

We are at home in all segments of industrial marking technology, and our dedicated and experienced engineers are proficient in various product tracking technologies. We place great emphasis on in-house, independent developments, after-sales services and 24/7 technology support.

Elevate your brand to a new level!

Contacts

Masterprint Jelöléstechnika Kft.

H-2454 Iváncsa, Kilencedi út 6.

Tel.: +36 1 203 8599

Fax: +36 1 204 8626

Email:

info@masterprint.hu